The application of low-temperature evaporators in electroplating wastewater treatment: reducing energy consumption and achieving sustainable development!

With the rapid development of industrialization, the electroplating industry, as an important surface treatment process, has become an important issue for environmental protection and sustainable development in terms of waste liquid treatment. Traditional electroplating wastewater treatment methods often suffer from high energy consumption and secondary pollution, while low-temperature evaporators, as a new type of wastewater treatment technology, have received widespread attention due to their high efficiency, energy conservation, and environmental protection characteristics. This article aims to explore the application of low-temperature evaporators in reducing energy consumption in electroplating wastewater treatment, and analyze its important significance for achieving sustainable development.

1、 Current Status and Challenges of Electroplating Waste Liquid Treatment

Electroplating waste liquid contains a large amount of heavy metal ions and organic compounds. If discharged directly without treatment, it will have a serious impact on the environment and human health. Traditional waste liquid treatment methods such as chemical precipitation and ion exchange can remove pollutants to a certain extent, but problems such as high energy consumption, long treatment cycle, and easy generation of secondary pollution cannot be ignored. Therefore, finding a technology that can efficiently treat waste liquid while reducing energy consumption has become a current research hotspot.

2、 The principle and advantages of low-temperature evaporators

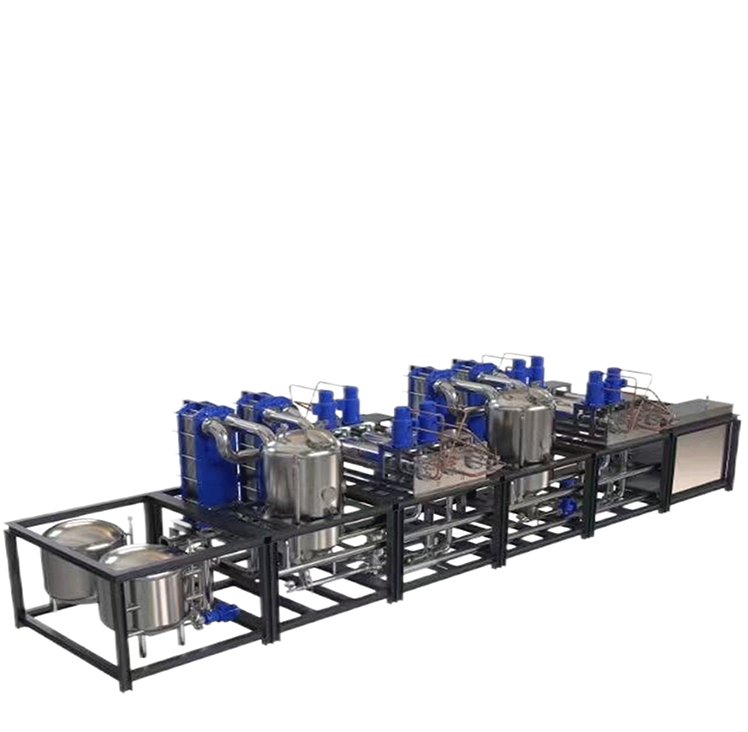

The low-temperature evaporator adopts advanced heat conduction technology to achieve efficient evaporation of waste liquid at low temperatures by controlling the temperature and pressure of the evaporation process. Compared to traditional evaporation technology, low-temperature evaporators have the following significant advantages:

Energy saving and consumption reduction: Low temperature evaporators operate at lower temperatures, reducing energy consumption and operating costs.

Efficient treatment: By optimizing the evaporation process, the efficiency of waste liquid treatment has been improved, and the treatment cycle has been shortened.

Environmental protection and emission reduction: Reducing the generation of secondary pollutants is beneficial for environmental protection and sustainable development.

3、 Application of Low Temperature Evaporator in Electroplating Waste Liquid Treatment

Applying low-temperature evaporators to the treatment of electroplating wastewater not only effectively removes heavy metal ions and organic compounds from the wastewater, but also significantly reduces energy consumption during the treatment process. In practical applications, low-temperature evaporators are usually combined with other treatment technologies, such as biological treatment, membrane separation, etc., to form a comprehensive treatment system and further improve the efficiency of waste liquid treatment.

4、 Case analysis

Taking a certain electroplating company as an example, the company introduced Yujia Environmental Protection low-temperature evaporator to treat electroplating waste liquid. After a period of operation, it was found that the efficiency of waste liquid treatment was significantly improved, while the energy consumption was reduced by about 45%. This achievement not only reduces the operating costs of the enterprise, but also earns a good environmental reputation for the enterprise, achieving a win-win situation of economic and environmental benefits.

Low temperature evaporator, as a new type of waste liquid treatment technology, has shown great potential and advantages in the treatment of electroplating waste liquid. Through practical application and case analysis, it has been proven that low-temperature evaporators have significant effects in reducing energy consumption, improving treatment efficiency, and reducing secondary pollution. Therefore, promoting and applying low-temperature evaporators is of great significance for the sustainable development of the electroplating industry.